Relied On Lift Maintenance Repair Solutions for Reliable Operation

Wiki Article

Unlocking the Secrets to Efficient Lift Repair Works: Expert Insights Revealed

In the realm of lift repair work and maintenance, uncovering the methods that bring about reliable and efficient service belongs to decoding an intricate problem. Expert insights function as the leading light via the maze of difficulties faced by upkeep specialists in the vertical transportation industry. By diving into the depths of positive methods, troubleshooting techniques, and the continual quest of skill improvement, the path to elevating upkeep requirements reveals itself. As we embark on this trip to demystify the tricks behind structured lift repair work, a globe of opportunities emerges, assuring a future where downtime is lessened, safety and security is focused on, and operational quality ends up being the norm.Common Lift Repair Service Challenges

An additional widespread obstacle in lift fixings is the absence of appropriate maintenance records. Without accurate upkeep records, fixing service technicians might battle to detect problems effectively or anticipate prospective problems. This can result in longer repair times and increased prices as service technicians function to troubleshoot issues without historic information to direct them.

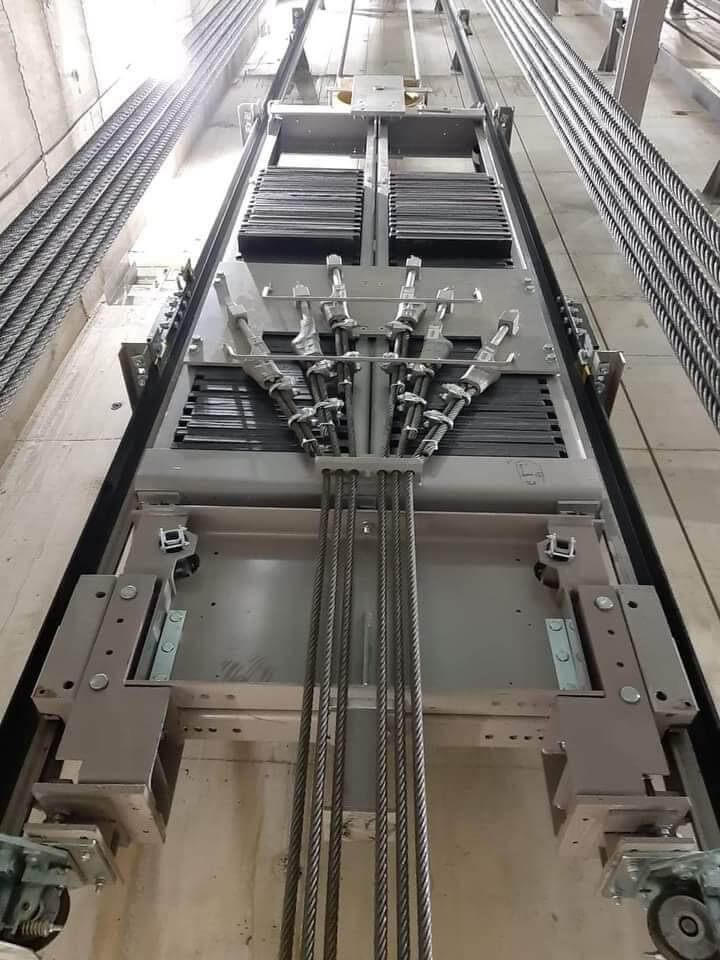

Additionally, accessibility concerns within lift shafts can present considerable challenges throughout repair services. Restricted room, awkward angles, and complex equipment can make it tough for specialists to get to the needed components for repair, prolonging the general repair work procedure - Lift Maintenance Repair. By attending to these common difficulties proactively, lift repair work professionals can enhance functional effectiveness and ensure the smooth performance of vertical transportation systems

Proactive Maintenance Strategies

Applying positive upkeep techniques is extremely important for making sure the longevity and optimal efficiency of lift systems. By adopting a positive approach to maintenance, structure managers and lift maintenance teams can address prospective concerns before they intensify right into costly repairs or downtime. One reliable strategy is to establish a normal upkeep schedule that includes comprehensive evaluations, lubrication of relocating components, and testing of security attributes.

Additionally, buying training programs for upkeep team can boost their abilities in recognizing possible problems and executing preventative upkeep jobs effectively - Lift Maintenance Repair. By empowering maintenance groups with the knowledge and devices required to proactively preserve lift systems, structure owners can lessen interruptions, prolong the life expectancy of their lifts, and guarantee a trusted and secure vertical transport experience for owners

Troubleshooting Methods

Efficient repairing techniques are crucial for immediately identifying and fixing concerns with lift systems to reduce downtime and guarantee optimal efficiency. One efficient technique is to start with a comprehensive aesthetic evaluation of the lift parts, checking for any kind of noticeable indications of imbalance, wear, or damages.

Enhancing Fixing Abilities

Enhancing effectiveness you can check here in lift system repair work is a basic aspect of making sure optimal performance and decreasing functional disruptions. Lift technicians should consistently work on refining their repair skills to meet the demands of modern-day lift systems.Furthermore, staying upgraded with the most up to date improvements in lift modern technology is essential for professionals seeking to boost their repair skills. This includes proactively inquiring concerning new components, software updates, and maintenance strategies to successfully detect and fix concerns. By investing effort and time into continuous knowing and functional experience, lift professionals can considerably increase their repair work proficiencies and add to the efficient functioning of lift systems.

Elevating Maintenance Criteria

Elevating maintenance standards in lift systems is paramount for ensuring prolonged operational effectiveness and security. Regular maintenance not only boosts the efficiency of lift systems however likewise decreases the risk of unexpected breakdowns and makes certain the safety and security of users. By sticking to stringent maintenance protocols, lift proprietors and operators can considerably minimize the probability of expensive repair work and downtime.Implementing a thorough upkeep routine that includes normal assessments, lubrication of moving parts, and aggressive replacement of used elements is important. Utilizing innovative innovations like IoT sensors and anticipating maintenance software program can assist in keeping an eye on the lift's condition in real-time, making it possible for prompt treatments before concerns intensify. In addition, supplying continuous training for upkeep staff on the current sector requirements and best methods is important for promoting maintenance quality.

Additionally, promoting a society of liability and interest to information among maintenance teams can better elevate maintenance requirements. Urging open communication channels for addressing and reporting maintenance worries without delay can help in maintaining a high degree of lift system integrity. Inevitably, by raising and focusing on upkeep criteria, lift systems can run efficiently and safely for a prolonged period.

Final Thought

In final thought, reliable lift fixings require proactive maintenance strategies, fixing strategies, and boosted fixing abilities. By addressing common challenges and elevating maintenance standards, upkeep specialists can properly make certain the smooth procedure of lifts - Lift Maintenance Repair. Applying these specialist insights can result in enhanced effectiveness, decreased downtime, and enhanced safety for both passengers and go to these guys toolsIn the world of view it now lift repair work and maintenance, uncovering the techniques that lead to efficient and reliable service is comparable to deciphering an intricate challenge.One more prevalent obstacle in lift repairs is the absence of appropriate maintenance documents. By embracing a proactive strategy to maintenance, structure supervisors and lift maintenance groups can attend to prospective concerns prior to they escalate right into costly fixings or downtime.In final thought, efficient lift repairs require aggressive maintenance approaches, fixing techniques, and improved repair abilities. By addressing usual challenges and boosting maintenance requirements, upkeep experts can efficiently make certain the smooth operation of lifts.

Report this wiki page